The Kaydeli glycol low temperature water chiller series delivers powerful, stable, and energy-efficient cooling for large-scale industrial applications requiring precise low-temperature performance. Available in capacities ranging from 30 to 600 tons (30HP–360HP), these chillers are engineered to support demanding processes across refrigeration, chemical production, pharmaceutical manufacturing, food processing, and other temperature-sensitive operations.

The Kaydeli glycol low temperature water chiller series combines robust industrial engineering with advanced refrigeration components to deliver high-capacity cooling performance. Featuring premium screw compressors, electronic expansion technology, and intelligent microcomputer control, this chiller ensures precise operation, reduced energy consumption, and enhanced system stability.

High-Performance Screw Compressors

Equipped with Taiwan “Chinese Variety” or German Bitzer screw compressors, engineered with highly precise rotor grinding technology to ensure smooth operation, high efficiency, and extended service life—ideal for large-capacity cooling systems.

Efficient Shell-and-Tube Evaporator

The shell-and-tube evaporator design features a low refrigerant charge, simple and reliable oil return, and does not require an oil pump. This reduces maintenance complexity while improving system reliability.

Electronic Expansion Valve for Precision Control

An intelligent electronic expansion valve ensures accurate refrigerant flow regulation, enhancing system energy efficiency and maintaining precise low-temperature performance.

Advanced Microcomputer Control System

The intelligent control platform provides stable operation, real-time monitoring, automatic protection, fault alarms, and precise temperature management to maximize system reliability and safety.

Deep Low-Temperature Capability

The unit provides chilled glycol outlet temperatures down to –20°C, supporting demanding industrial processes and ensuring temperature stability under continuous operation.

Optional Building & Group Control Integration

Supports advanced centralized management, building automation system (BAS) interfacing, and multi-unit group control—ideal for large industrial facilities with complex process cooling demands.

Chemical reaction cooling

Food freezing and deep-chilling production

Industrial refrigeration lines

Pharmaceutical and biotech processing

Resin, polymer, and material production

Low-temperature storage rooms

Industrial cooling for large-scale factories

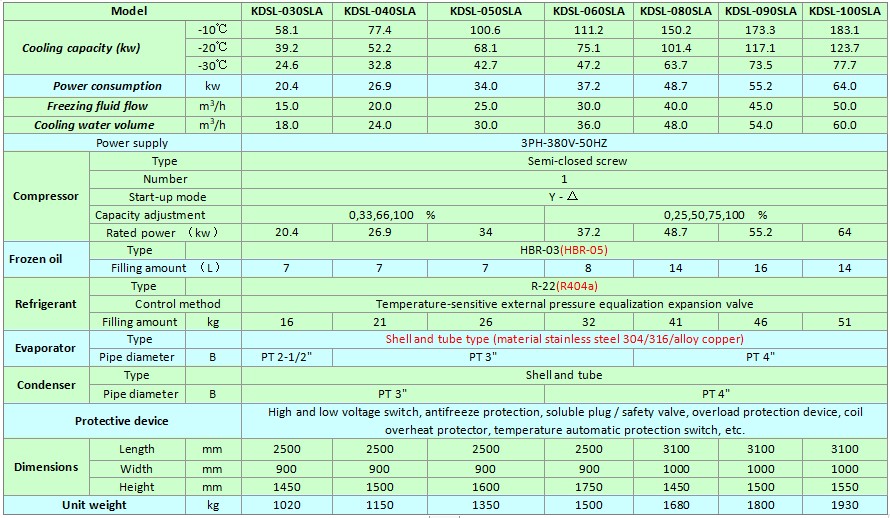

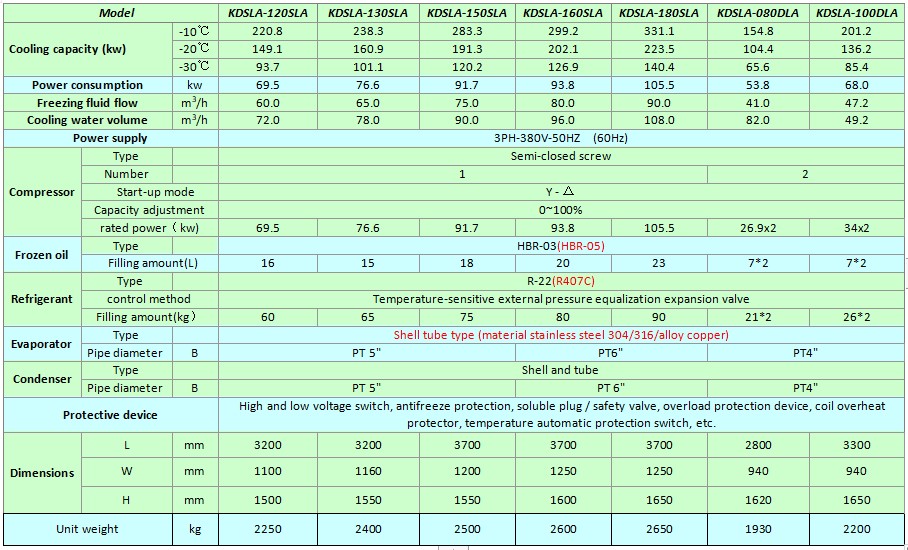

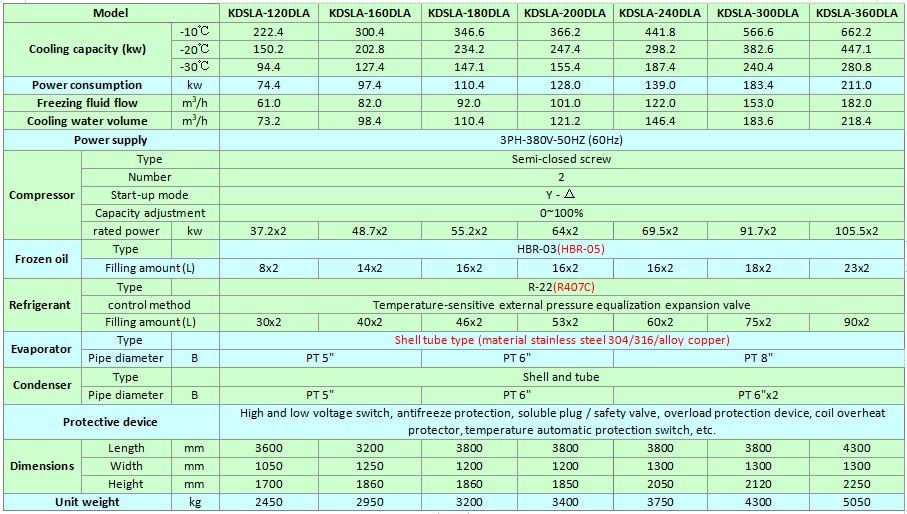

Water Screw Chiller Specification(-10℃,-20℃,-30℃):

By continuing to use the site you agree to our privacy policy Terms and Conditions.