Surface treatment plays a vital role in enhancing the appearance, performance, and durability of industrial components. However, maintaining the quality and consistency of these treatments heavily relies on precise temperature control. In this article, we’ll explore the main types of surface treatment processes and how tailored temperature control solutions—such as precision chillers—ensure reliable results in various applications.

To begin with, the surface treatment process refers to a series of techniques used to alter the surface of a material—usually metal or plastic—to improve its appearance, corrosion resistance, wear resistance, or electrical properties. These treatments are widely used in industries like automotive, aerospace, electronics, and manufacturing.

Electroplating

Anodizing

Powder coating

Phosphating

Chemical polishing

Each method has specific requirements in terms of chemical reactions and operating temperature ranges.

Consistent temperature is one of the most important factors that determine the quality of a surface treatment process. Temperature variations can affect:

Chemical reaction rates

Layer thickness and uniformity

Adhesion and surface finish

Bath stability and energy consumption

For example, in electroplating, maintaining a stable bath temperature is essential to achieve even deposition and avoid defects. This is where industrial chillers and temperature control systems come into play.

Different surface treatment lines require tailored cooling or heating systems depending on the process involved. Below are the most commonly used temperature control solutions in surface treatment plants:

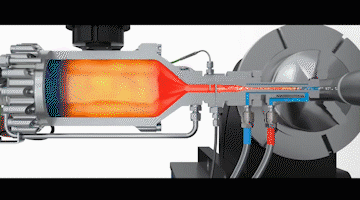

Precision chillers are ideal for controlling the temperature of plating baths, anodizing tanks, or chemical polishing units. These chillers offer tight temperature accuracy and fast response to load changes.

A dedicated electroplating cooling system is used to remove excess heat from plating tanks. It helps maintain the chemical bath at an optimal operating temperature, typically between 20°C and 30°C, depending on the metal being plated.

For general surface finishing lines, water chillers provide a cost-effective solution. These water chiller systems can be air-cooled or water-cooled depending on site conditions and cooling capacity requirements.

Using a reliable temperature control system ensures stable production, improved product quality, and energy efficiency. Surface treatment workshops benefit from:

Increased coating uniformity

Fewer reworks or defects

Extended lifespan of chemical baths

Reduced energy waste

By integrating industrial chillers into surface treatment lines, businesses can gain better control of their processes and lower operational costs.

When selecting an industrial chiller for surface treatment applications, consider:

Cooling capacity (kW or tons)

Temperature accuracy requirements

Resistance to corrosion (especially for chemical environments)

Ease of integration with existing systems

Working with a trusted chiller manufacturer ensures you receive a customized solution that fits your technical needs and process requirements.

In summary, surface treatment processes demand strict temperature control to guarantee consistent, high-quality results. Precision chillers, electroplating cooling systems, and tailored water chiller units help stabilize these processes and reduce the risk of defects or downtime.

As a reliable industrial chiller supplier, Kaydeli continues to provide efficient and customized temperature control solutions to support various surface treatment applications around the world. Contact us to learn how our advanced chiller systems can enhance your production line.

By continuing to use the site you agree to our privacy policy Terms and Conditions.