We offer you 100% custom-made service Inquiry

In modern chemical production, improving energy efficiency is just as important as product quality. Nano calcium carbonate is widely used in plastics, rubber, coatings, and paper industries, but its production requires strict temperature control and high energy consumption. By using advanced solutions such as chiller systems and high temperature heat pumps, manufacturers can achieve better stability and significant cost savings.

To begin with, nano calcium carbonate production involves chemical reactions and crystallization processes that are highly sensitive to temperature changes. If the temperature is not stable, the particle size and quality of the final product can be affected. Traditional cooling and heating methods often waste large amounts of energy, leading to high operational costs. This is why industries are turning to modern energy-saving solutions.

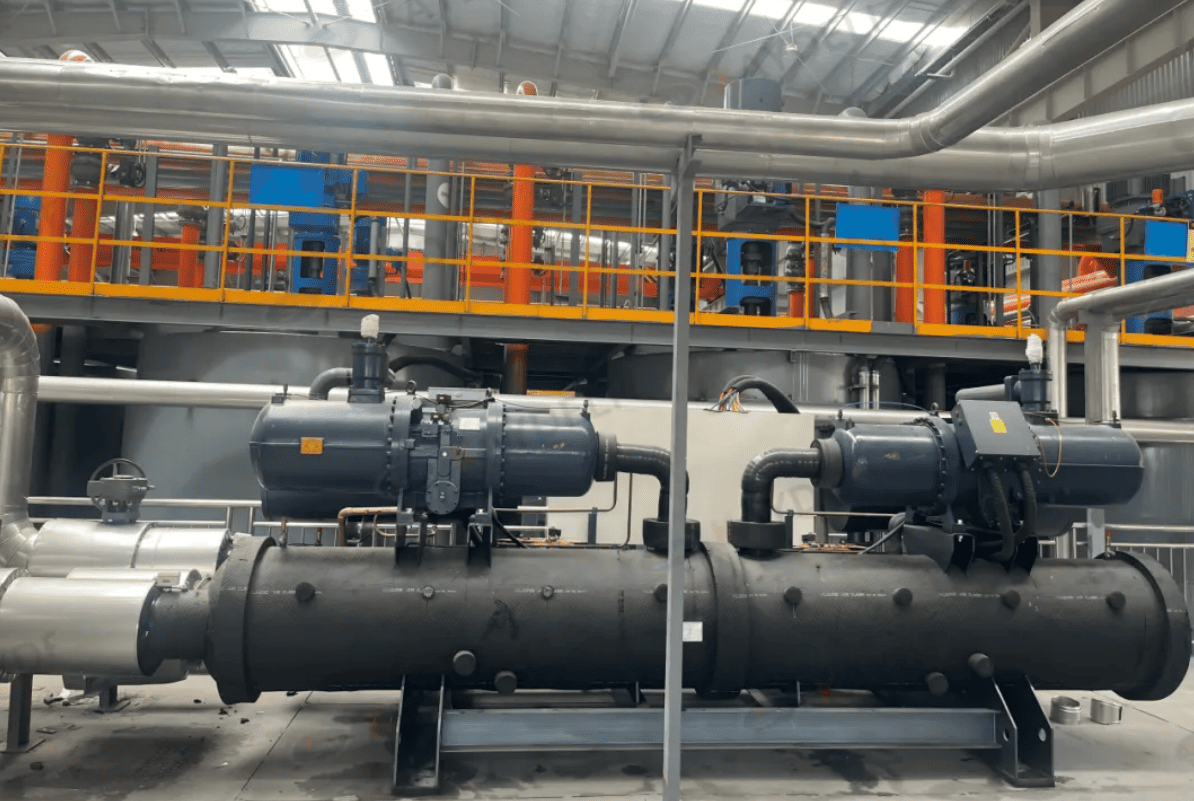

Chiller systems play a central role in controlling process temperatures. They provide consistent cooling water for reactors, mixers, and other production equipment. With a reliable industrial water cooled screw chillers, manufacturers can avoid overheating, maintain stable reaction environments, and ensure consistent product quality. At the same time, optimized cooling also reduces energy waste and improves equipment lifespan.

In addition to cooling, heating is also necessary during nano calcium carbonate production. This is where high temperature heat pumps provide an advantage. Instead of relying on traditional boilers that consume large amounts of fuel, heat pumps can recover waste heat from the cooling process and reuse it for heating. This dual function not only reduces energy costs but also minimizes carbon emissions. As a result, high temperature heat pumps support both efficiency and sustainability.

When chiller systems and high temperature heat pumps are used together, the benefits multiply. The chiller maintains cooling precision while the heat pump recycles waste heat, creating a closed-loop energy cycle. This integration means less energy loss, lower costs, and stable production performance. In large-scale nano calcium carbonate plants, this combination has become one of the most effective ways to achieve energy saving in nano calcium carbonate production.

Another important point is that energy-saving technologies help manufacturers reduce operating costs in the long run. By lowering electricity and fuel consumption, production plants can significantly cut expenses. At the same time, reducing carbon emissions and improving energy efficiency align with global sustainability goals. In this way, using chiller systems and heat pumps benefits both the business and the environment.

In summary, the production of nano calcium carbonate requires precise and efficient temperature control. The combined use of chiller systems and high temperature heat pumps provides a proven way to achieve stability, energy savings, and sustainable growth.

At Kaydeli, we specialize in advanced temperature control technologies that support industries worldwide. As a trusted industrial chiller supplier, we provide reliable solutions tailored to your production needs. Contact KAYDELI today to explore how our systems can help your business achieve higher efficiency and long-term success.

By continuing to use the site you agree to our privacy policy Terms and Conditions.