We offer you 100% custom-made service Inquiry

The Crystal Growth Furnace System is a device used to prepare single crystals. It usually consists of a vacuum chamber, a vacuum system and an inflation system, a heating system, a lifting and rotating mechanism, a measurement and control system for temperature and pressure, and other auxiliary equipment. This system requires very precise control and transmission.

The working principle of the crystal growth furnace is mainly based on the melting method or the gas phase method. In the melting method, the crystal growth furnace heats the raw material or furnace material to a high temperature to melt it into a molten liquid. A crystal seed or substrate is then placed in the melt in a suitable manner and gradually withdrawn from it. As the crystal seeds are extracted, the molten liquid will crystallize on the seeds to form a single crystal. The crystal growth furnace controls the growth rate and quality of the crystal by controlling parameters such as temperature, pressure, and extraction speed.

In the gas phase method, the crystal growth furnace generates active species by heating raw materials in the gas phase. These active species are deposited on the crystal substrate under appropriate conditions and gradually grow into single crystals. The crystal growth furnace also controls the growth rate and quality of the crystal by controlling parameters such as temperature, gas flow, and chemical reaction conditions.

Crystal growth furnace systems are widely used in semiconductor, optics, laser, superconducting, ceramics and other fields, providing necessary equipment and technical support for the preparation of high-quality single crystal, polycrystalline, thin film and other crystal materials.

A chiller is required in a crystal growth furnace system to maintain a stable temperature within the system. The furnace heats the material to a high temperature, but it is important to cool the surrounding environment to prevent unwanted reactions and maintain a stable temperature for crystal growth. A chiller circulates a coolant, typically water, through the system to remove excess heat and maintain a stable temperature. The temperature of the coolant can be adjusted to control the temperature of the system, allowing for precise control of the crystal growth process. Without a chiller, it would be difficult to maintain a stable temperature and optimize crystal growth.

Here is one of our recent project for an African crystal growth company.

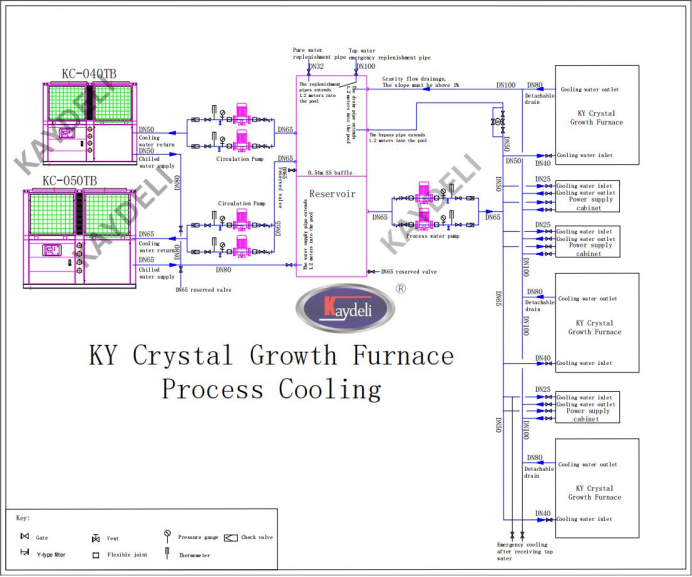

In this project Kaydeli used two of their air cooled chillers KC-040TB and KC-050 TB to accomplish the project.

A total of five crystal growth furnaces are installed in this process, three KY crystal growth furnaces, and two GT crystal growth furnaces. The maximum production load operation does not exceed three crystal growth furnaces, and each cycle corresponds to the maintenance of different crystal growth furnaces.

The cooling water demand for a single unit of KY crystal growth furnace equipment is: 6m³/h, the constant temperature of the cooling water supply is 28°C±1°C, the water inlet pressure of the crystal growth furnace is 0.2MPa-0.22MPa. The gravity flow returns water, and the water inlet pressure of the power cabinet 0.2MPa-0.3MPa. The outlet water temperature rises by 5~7°C.

Here is the design of a set of cooling circulating water system, using air-cooled industrial chiller to cool down the normal temperature water in the 12 cubic reservoir to the set temperature, and then the cold water in the reservoir is delivered to the crystal growth furnace equipment by the process water pump.

Two air-cooled industrial chillers are selected, one with a cooling capacity of 113.1KW (the other one has a cooling capacity of 141.4KW), an overall unit composed of four compressors, four independently operating refrigeration systems, process water pumps, air conditioning circulation pumps and, centrifugal pumps. The material of the water supply and return pipes is 304 stainless steel(SS), and each device is equipped with 304 stainless steel (SS) valves. The air-cooled industrial chiller integrates the refrigeration system, water tank, and water pump for easy use and operation. The unit is compact and occupies a small area. It can be used when it is connected to water and electricity.

Intelligent control, using high-precision LCD digital controller, can intuitively and accurately measure the outlet water temperature, the operation panel can intuitively display the operation and fault status of the compressor, water pump, refrigeration system at a glance. Only pressing the start and stop button can run the equipment automatically. Simple operation and convenient.

Please feel free to contact Kaydeli for any kinds of support in this field as well as for any Industrial chiller requirements.

By continuing to use the site you agree to our privacy policy Terms and Conditions.